Visual Inspection. Virtual Metrology. Advanced Process Control.

AI Inspection Software For

Semiconductor Manufacturing

Train custom AI inspection models for semiconductor manufacturing in hours, using just 20-40 images per defect. Our deep learning engine delivers near-zero false positives, boosting yield without requiring data scientists or extensive training data.

Key Features

Powering Next-Generation Semiconductor Manufacturing

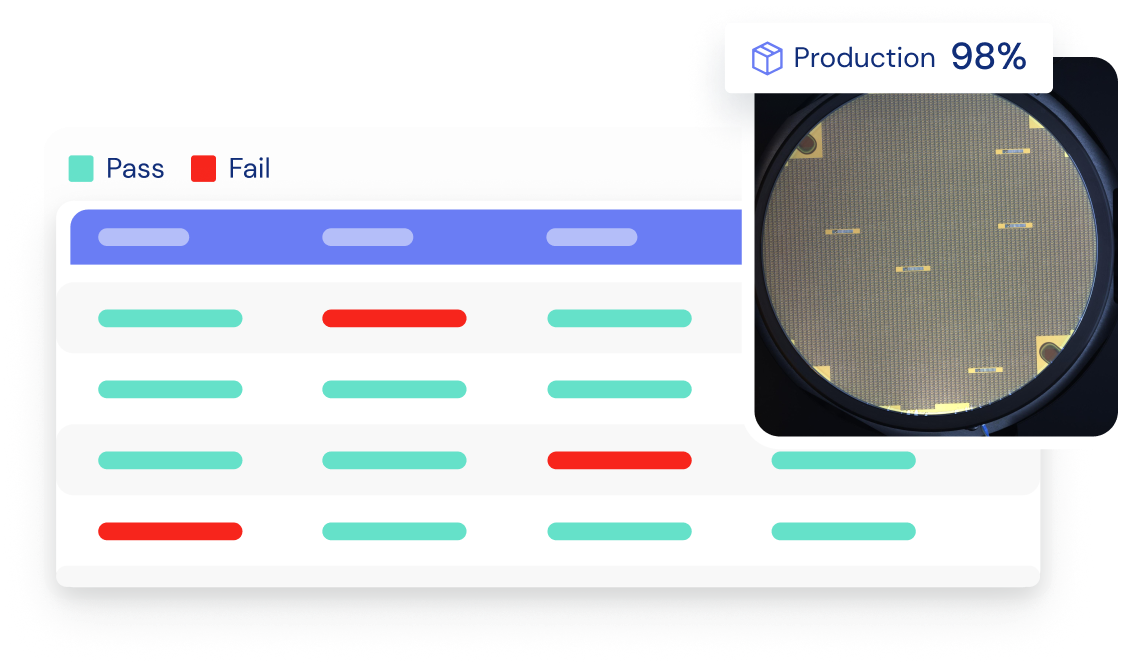

Automated Judgment and Defect Review

Accelerate semiconductor manufacturing with automated inspection technology. Our advanced software delivers real-time defect detection, intelligent classification, and streamlined review processes, minimizing human intervention.

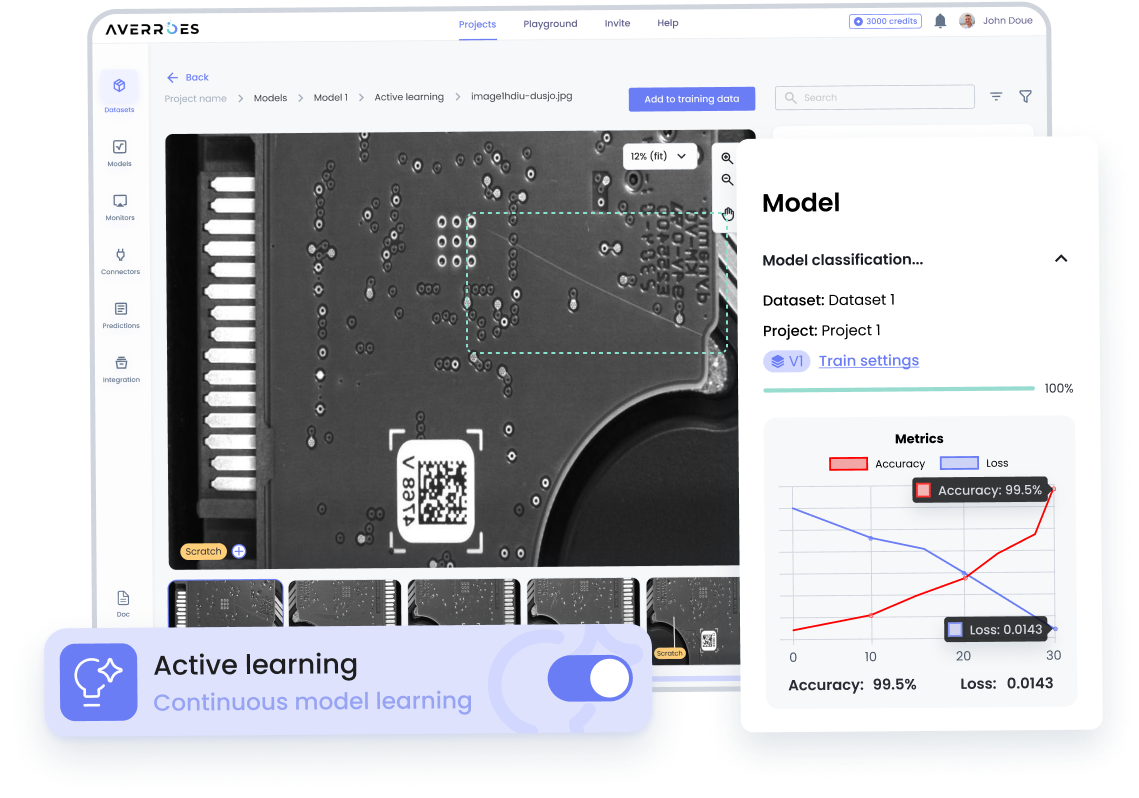

Continuous Learning

Our AI continuously learns from new data, enhancing defect detection and classification in real time. Unlike traditional inspection systems constrained by pre-programmed defects, our platform adapts to identify new and emerging issues, boosting inspection flexibility and efficiency.

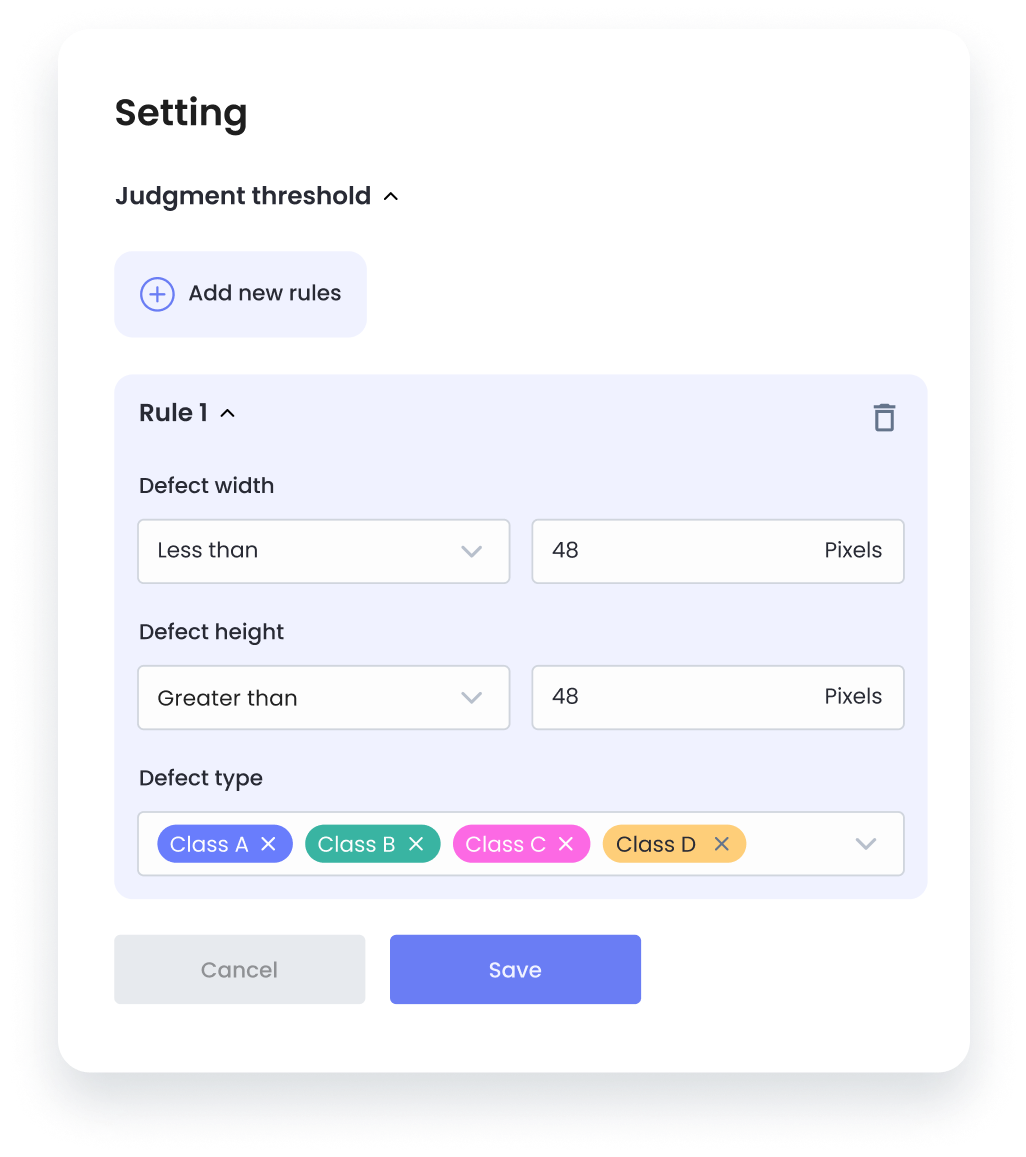

Near Zero False Positives

Achieve unmatched accuracy with our advanced AI, designed to significantly reduce false positives using precise judgment criteria. This ensures only genuine defects are flagged, addressing the inefficiencies of traditional inspection systems that often yield high false positive rates.

Smart Augmentation

Our deep learning model enhances defect detection across varying lighting and environmental conditions, ensuring thorough inspections. Unlike traditional systems that often miss defects from seal or glue errors, our advanced imaging technology delivers precise results without requiring extra investments.

Real-Time Inspection and Monitoring

Drive manufacturing efficiency with instant data analysis and automated defect detection at production speeds. Our AI platform delivers comprehensive insights through an interactive dashboard, enabling real-time process control and quality management.

Seamless Integration and Scalability

Seamlessly incorporate AI inspection capabilities into your existing semiconductor manufacturing workflow. Our scalable software platform adapts to both emerging companies and established semiconductor industry leaders, supporting growing production demands and compute requirements while maintaining consistent quality control across your business operations.

Virtual Metrology

Achieve accurate parameter predictions in just 5 seconds—compared to the 2.5 hours typical of traditional models. Our AI virtual metrology solutions measure critical parameters, such as surface roughness, with precision.

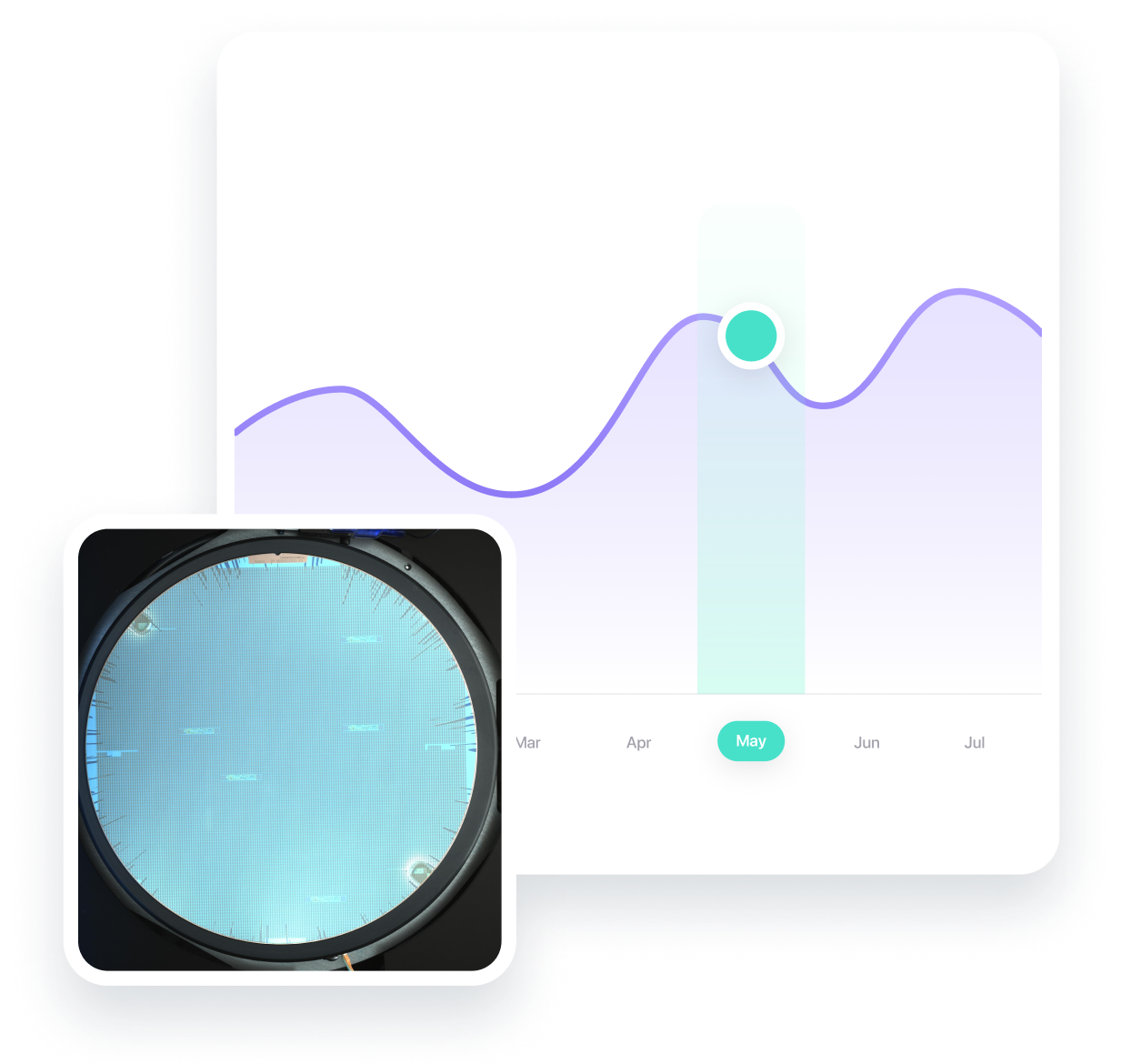

Yield Optimization & Process Control

Our AI technology platform combines automated inspection with data-driven insights to optimize production yield and quality. By integrating virtual metrology with intelligent manufacturing controls, we deliver precise measurements and process improvements that scale with your business demands.

Learn more

Flexible Deployment, Security, and Privacy

Deploy our solution based on your requirements—whether fully offline with our on-premise option, in the cloud, or on a private cloud. Our platform adheres to the highest standards of security and privacy, ensuring your sensitive data is protected while optimizing operational efficiency.

Frequently asked questions

AI-powered visual inspection utilizes advanced algorithms to automate defect detection and classification, enhancing quality control and operational efficiency in semiconductor manufacturing.

Experience the Averroes AI Advantage

Elevate Your Visual Inspection Capabilities

Request a Demo Now