Transform Your Existing

Visual Inspection System with AI

No new hardware. No process changes.

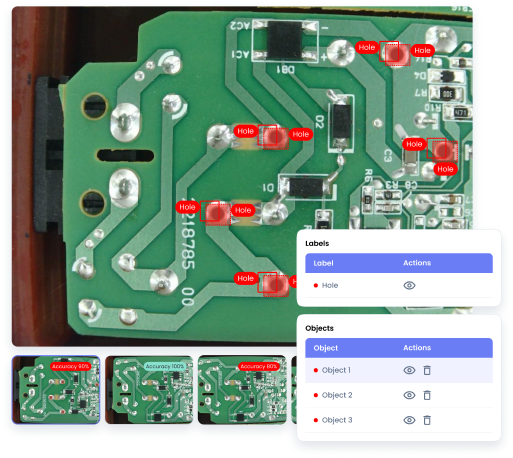

High-Precision Defect Segmentation with Minimal Training Data

Train models to accurately segment images with minimal labeled data by leveraging prior knowledge and adapting to new tasks quickly.

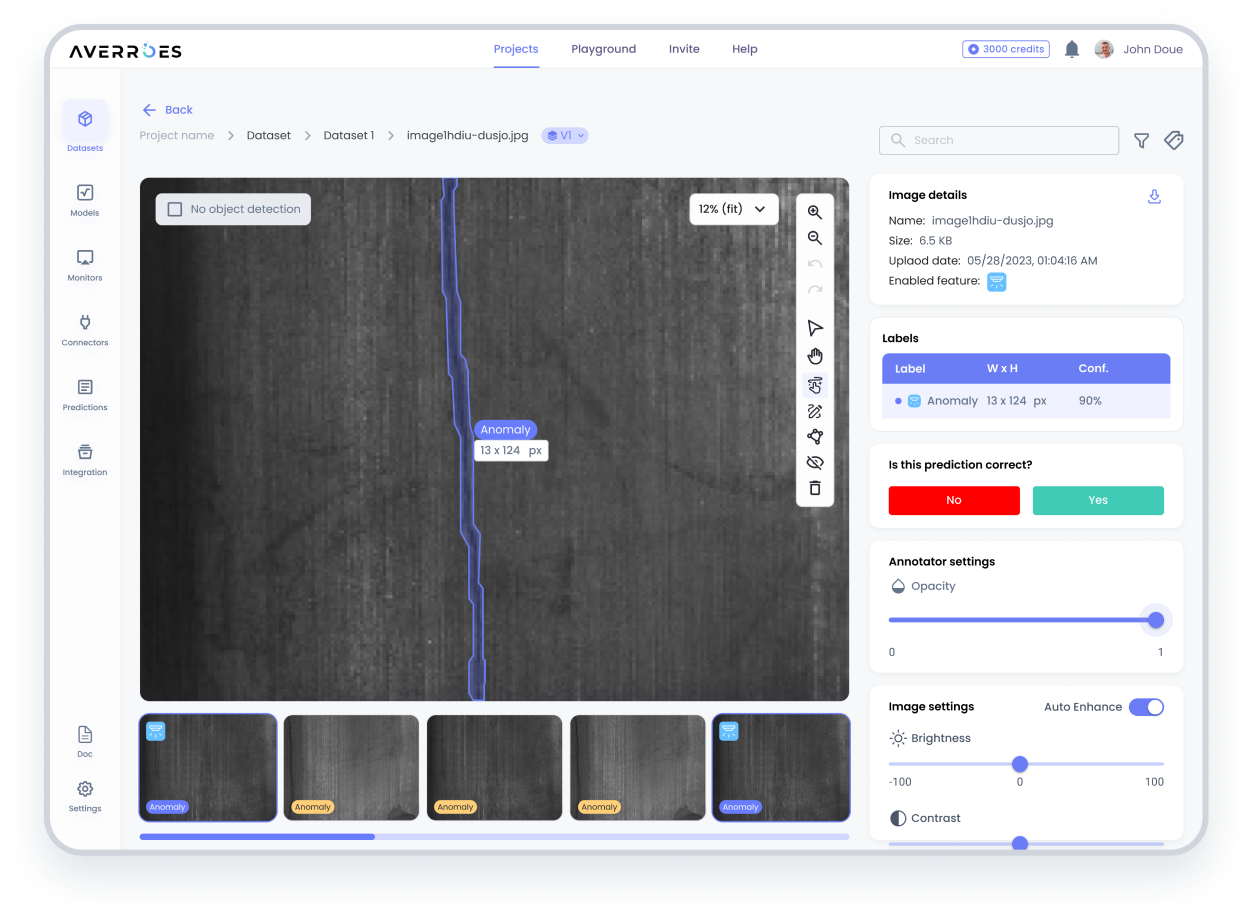

Our intuitive labeling tool enables users to annotate images swiftly, simplifying the data preparation phase. This efficiency allows your team to focus on what truly matters—achieving exceptional accuracy in defect classification.

At the heart of our system is a sophisticated object detection engine that utilizes advanced machine learning algorithms. Adaptable to your specific requirements, it efficiently identifies and categorizes defects with near-zero false positives, setting a new standard in automated defect detection.

Deploying custom AI models has never been easier. Our platform supports quick and seamless model deployment, allowing your team to integrate AI-driven inspections into your workflow without significant disruptions—enhancing productivity from day one.

Leverage the power of feedback learning to enhance your defect classification system continuously. Our technology learns from new data, refining algorithms to improve accuracy and performance, ensuring your inspections remain ahead of evolving production challenges.

Human-Centric Feedback Adaptation

Refine models effortlessly with our human-centric feedback adaptation feature. The engine allows for incremental improvements without the need for full retraining, leveraging meta learning to integrate specific engineer feedback and new data efficiently.

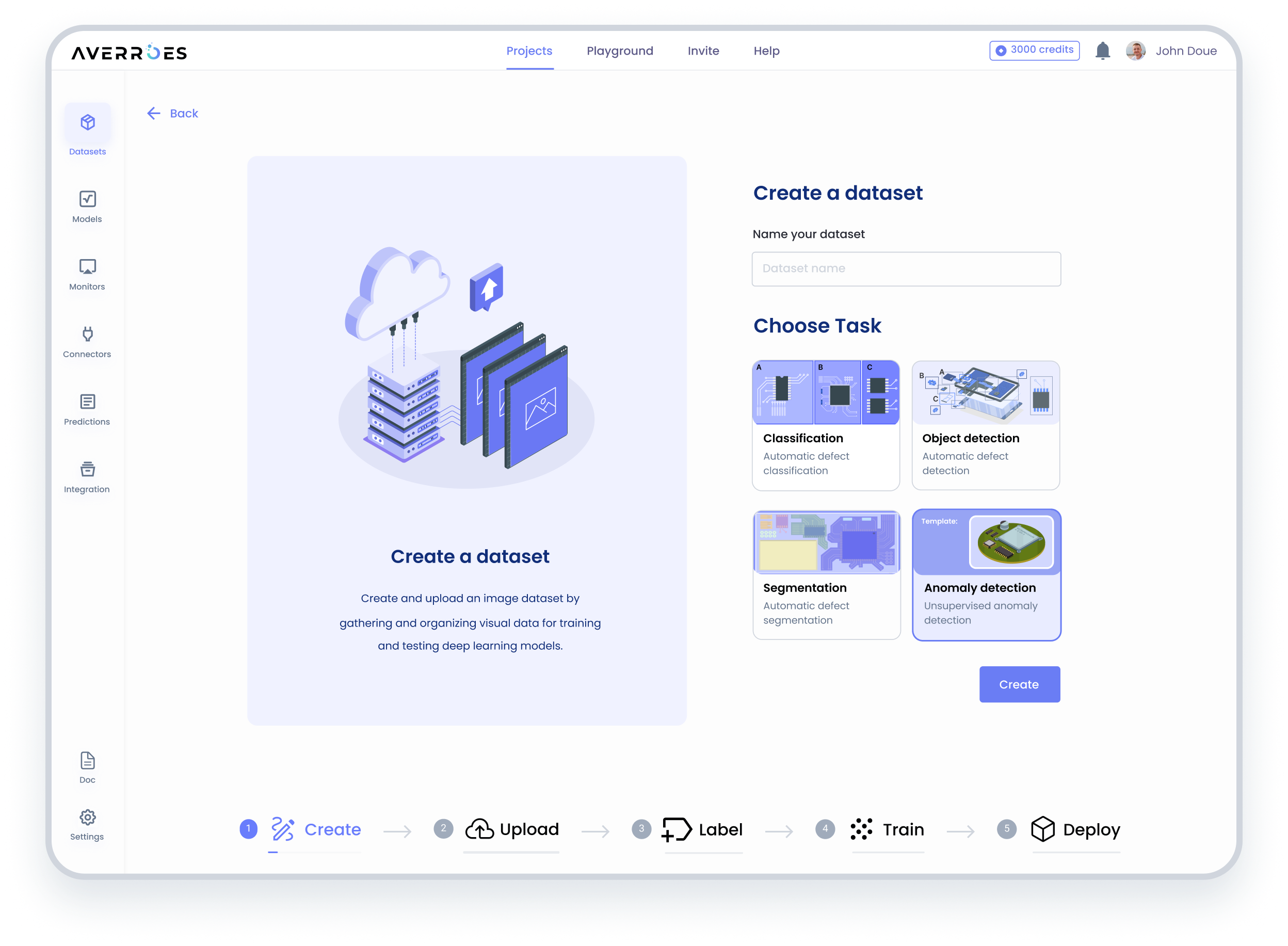

No-Code AI Platform

Build and deploy your custom AI models effortlessly with our no-code AI platform. Whether you’re addressing accuracy issues in existing visual inspection equipment or seeking a tailored automated defect classification model, our user-friendly interface makes it simple and efficient—just a few steps away.

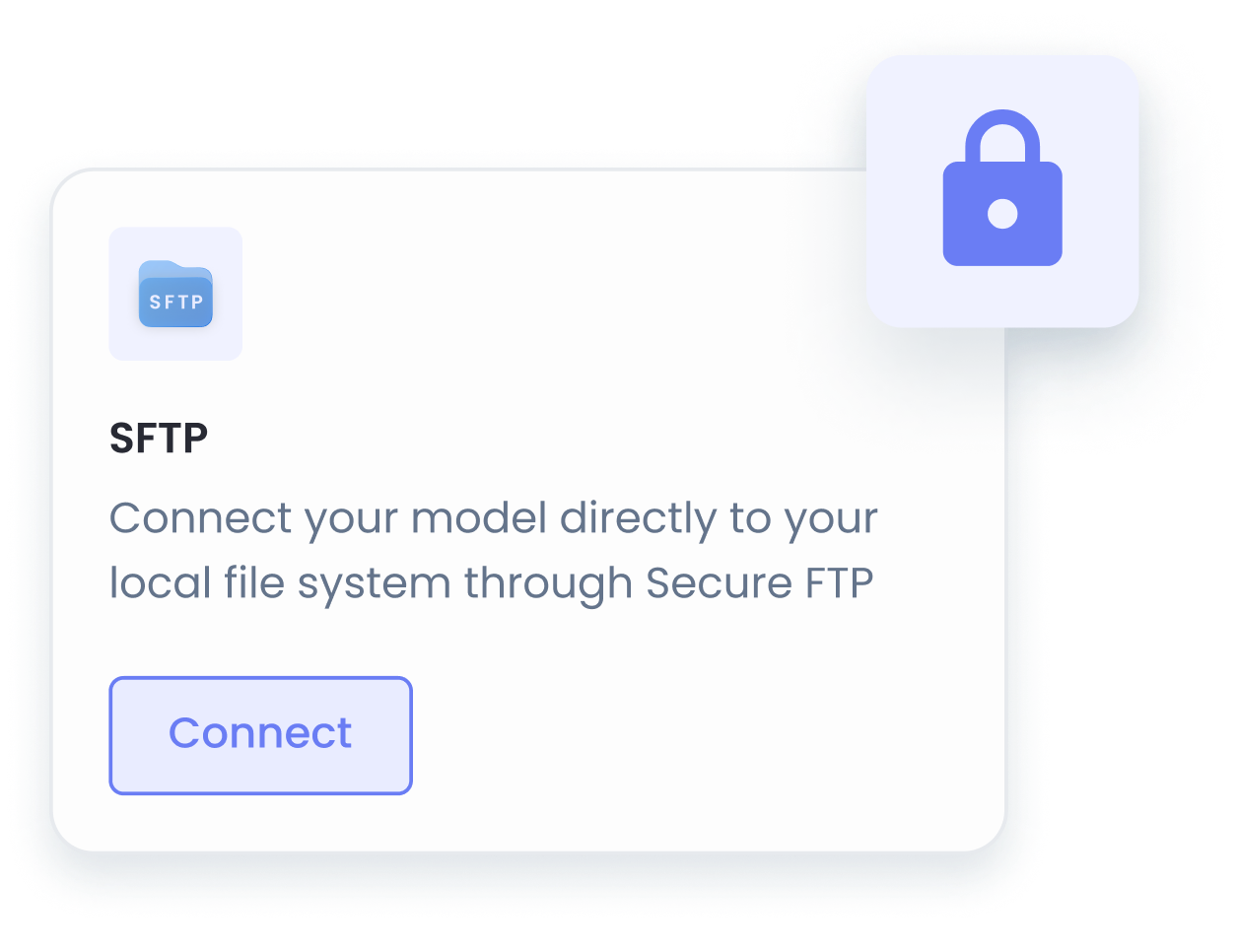

Privacy and Security

Choose between on-premise solutions for enhanced privacy, speed, and security, or opt for our cloud-based platform for unparalleled scalability and performance. As a cloud-agnostic provider, we ensure seamless integration and flexibility, allowing you to select the best deployment option that aligns with your operational requirements.

Continuously Learns from Data

Unlike traditional, expensive software 1.0 based equipment, our Automated Defect Segmentation model continuously learns from data, enhancing its accuracy over time. Utilizing the Active Learning feature, our system adapts to new information, ensuring your defect detection capabilities remain cutting-edge and reliable.

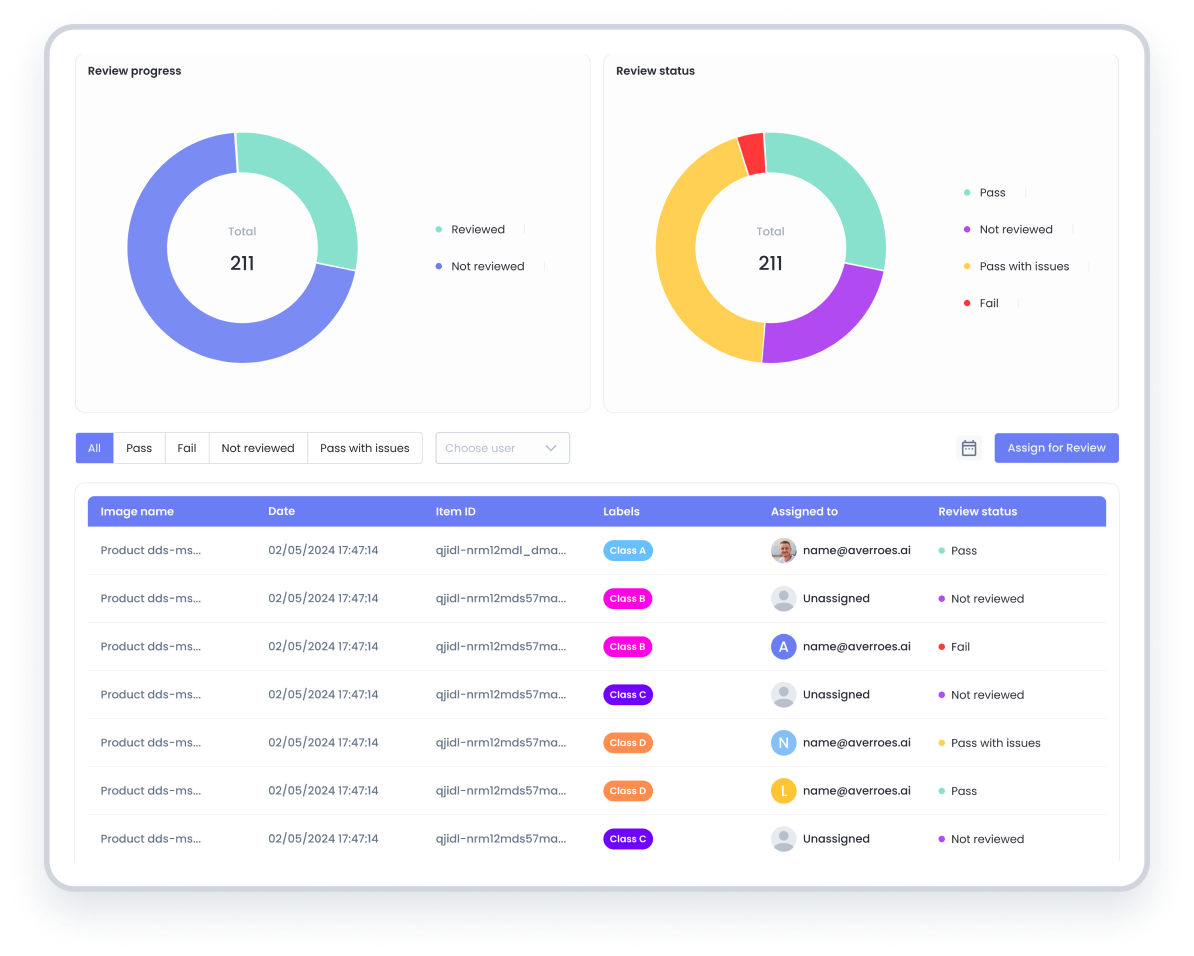

Automate Defect Judgment Process

Set thresholds to target the defects that matter most to your operations. Our automated defect judgment process allows your team to concentrate on throughput and yield improvement while we handle defect evaluation. This system removes subjectivity, ensuring objective assessment and reliable outcomes in your defect detection workflow.

Capture Unknown Defects

The Averroes WatchDog feature ensures that no defect goes uncaught. Unlike traditional equipment, which only identifies pre-configured defects, Averroes excels at detecting unknown anomalies in your manufacturing process.

_pixian_ai 1.png)

Complete Storytelling

Analyze defects, wafers, and masks from A to Z with our comprehensive reporting capabilities. Gain valuable insights from historical data to understand the full story behind each defect.

We've experienced a remarkable 40-60% increase in submicron defect detection. Averroes has saved us over 300 hours/month/app of labor and increased our productivity by more than 30% .

Automation Manager @ Semiconductor OEM

Frequently asked questions

Automated defect detection uses AI and machine learning algorithms to identify, classify, and analyze defects in manufacturing processes, improving efficiency and accuracy.

Experience the Averroes AI Advantage

Elevate Your Visual Inspection Capabilities

Request a Demo Now