Why Choose Our Advanced

Process Control System?

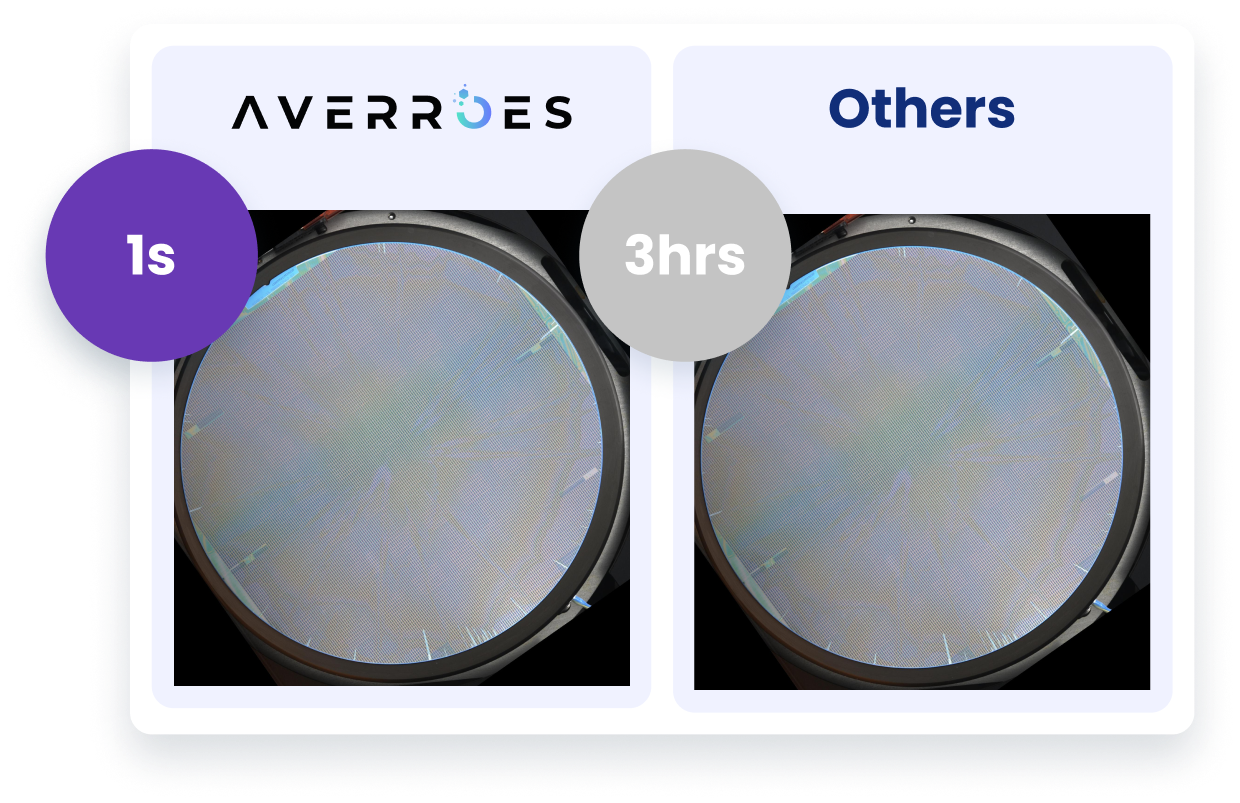

Designed to address the intricate challenges of semiconductor manufacturing, our solution leverages AI and ML to foresee and mitigate process deviations. This ensures that fabrication remains within exacting parameters, leading to higher yields and reduced defects.

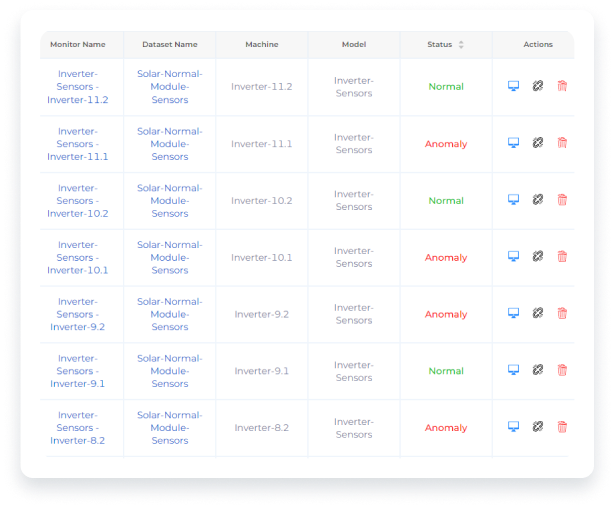

Real-Time Drift Prediction and Management

Integration with Smart Manufacturing Systems

Statistical Process Control Enhancements

Deep Learning-Based Environment Emulation and Virtual Metrology

Proactive Equipment Maintenance

Impact of APC

on Manufacturing

Implementing AI and machine learning in our APC systems revolutionizes manufacturing from reactive to proactive. This transformation enhances precision and efficiency in semiconductor fabrication, significantly reducing costly errors and improving overall equipment effectiveness (OEE).

By predicting process drift and executing real-time adjustments, our APC systems ensure adherence to the rigorous quality standards that advanced semiconductor manufacturing demands.

Experience the Averroes AI Advantage

Elevate Your Visual Inspection Capabilities

Request a Demo Now