AI Defect Monitoring For Manufacturing Excellence

Automated AI Defect Monitoring & Screening

Optimize production with real-time defect monitoring, customizable alerts, and AI insights. Integrate seamlessly for instant or batch predictions, ensuring proactive management, reduced downtime, and improved quality.

Precision in Every Defect

Monitor, Analyze, Optimize, Evolve

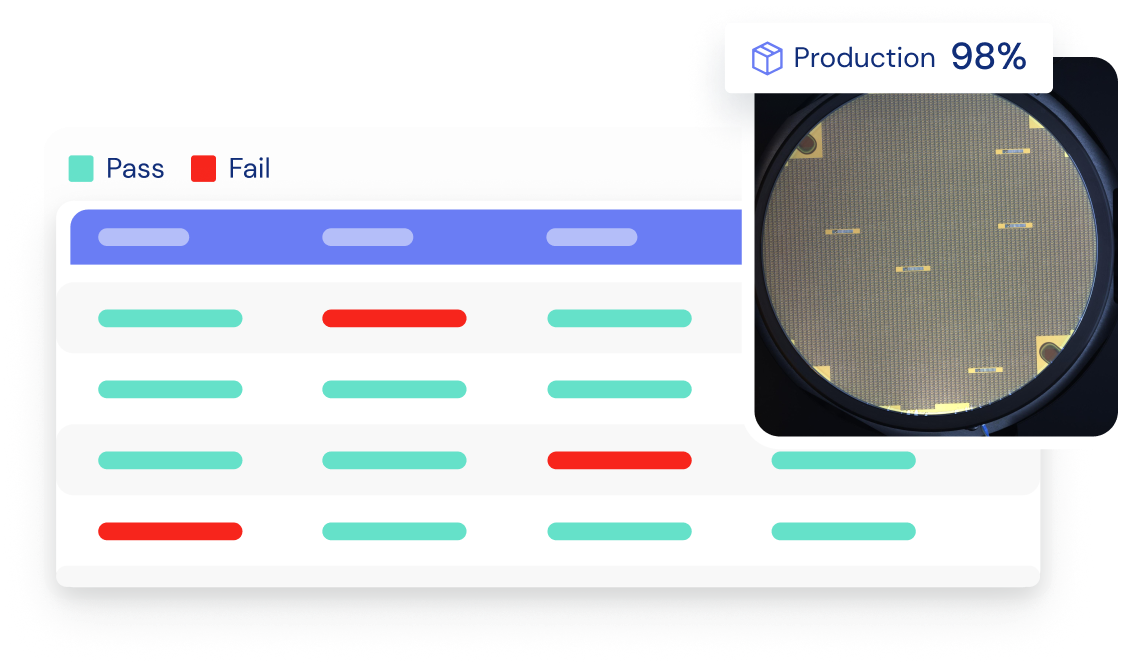

Real-Time Defect Monitoring Dashboard

Stay informed with our real-time defect Monitoring dashboard. This comprehensive tool provides instant visibility of all defects, enabling quick responses from anywhere. Enhance production quality and efficiency by leveraging actionable insights to address issues proactively.

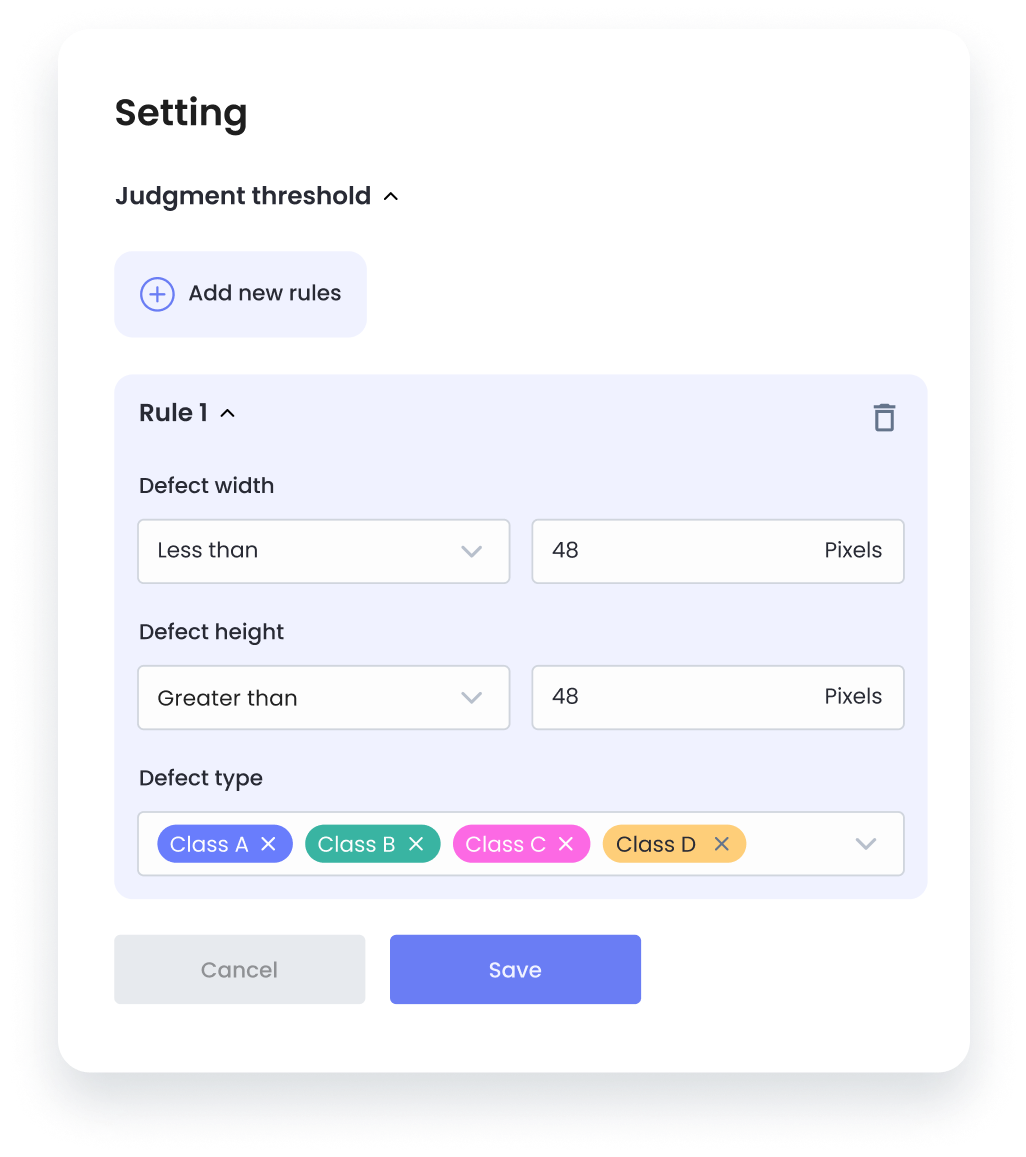

Smart Defect Alert

Utilize smart defect alerts to customize notifications based on defect coordinates and thresholds. This feature enables early detection of recurring issues, ensuring prompt intervention. Minimize production downtime and maintain high yield for seamless operations.

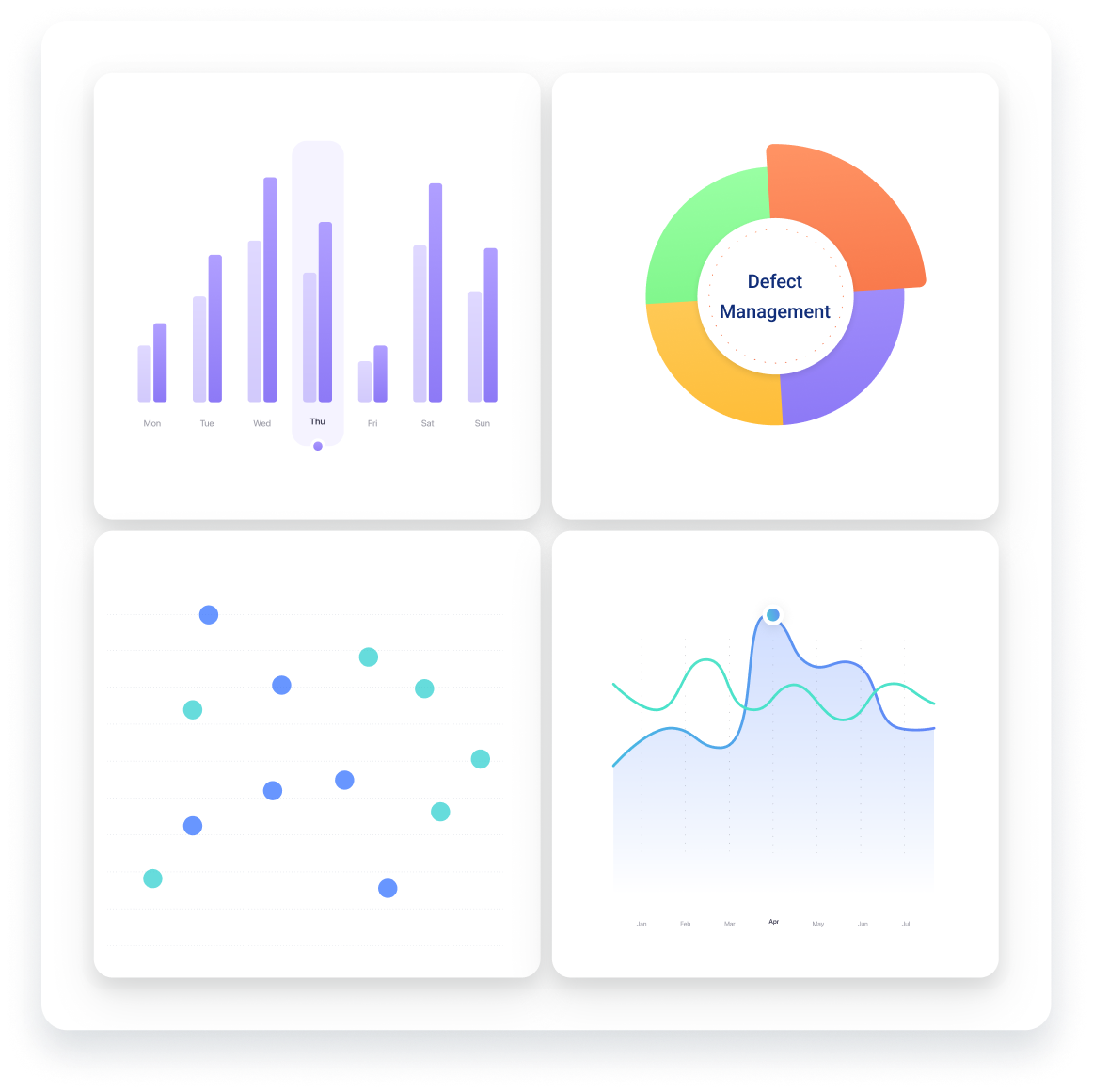

AI-Powered Defect Management

Gain real-time insights into defect trends with our AI-powered defect management system. Leveraging advanced AI, this solution provides actionable data for informed decision-making. Optimize your production processes and ensure proactive management of defects to enhance quality and efficiency.

Continuously Learns from Data

Our solution adapts as your production needs evolve. Designed for scalability, it easily accommodates new defect types, materials, and process innovations. This model ensures lasting adaptability, eliminating the need for frequent hardware upgrades while maintaining peak performance.

Dynamic Data Connector

Effortlessly connect to your data sources with our Dynamic Data Connector. This feature enables real-time or batch predictions, ensuring efficient data integration. Experience continuous and accurate updates to your predictive models, enhancing both production quality and decision-making.

We've experienced a remarkable 40-60% increase in submicron defect detection. Averroes has saved us over 300 hours/month/app of labor and increased our productivity by more than 30% .

Automation Manager @ Semiconductor OEM

Frequently asked questions

AI defect monitoring uses advanced algorithms to identify and analyze defects in manufacturing processes, enhancing quality control and minimizing errors.

Experience the Averroes AI Advantage

Elevate Your Visual Inspection Capabilities

Request a Demo Now