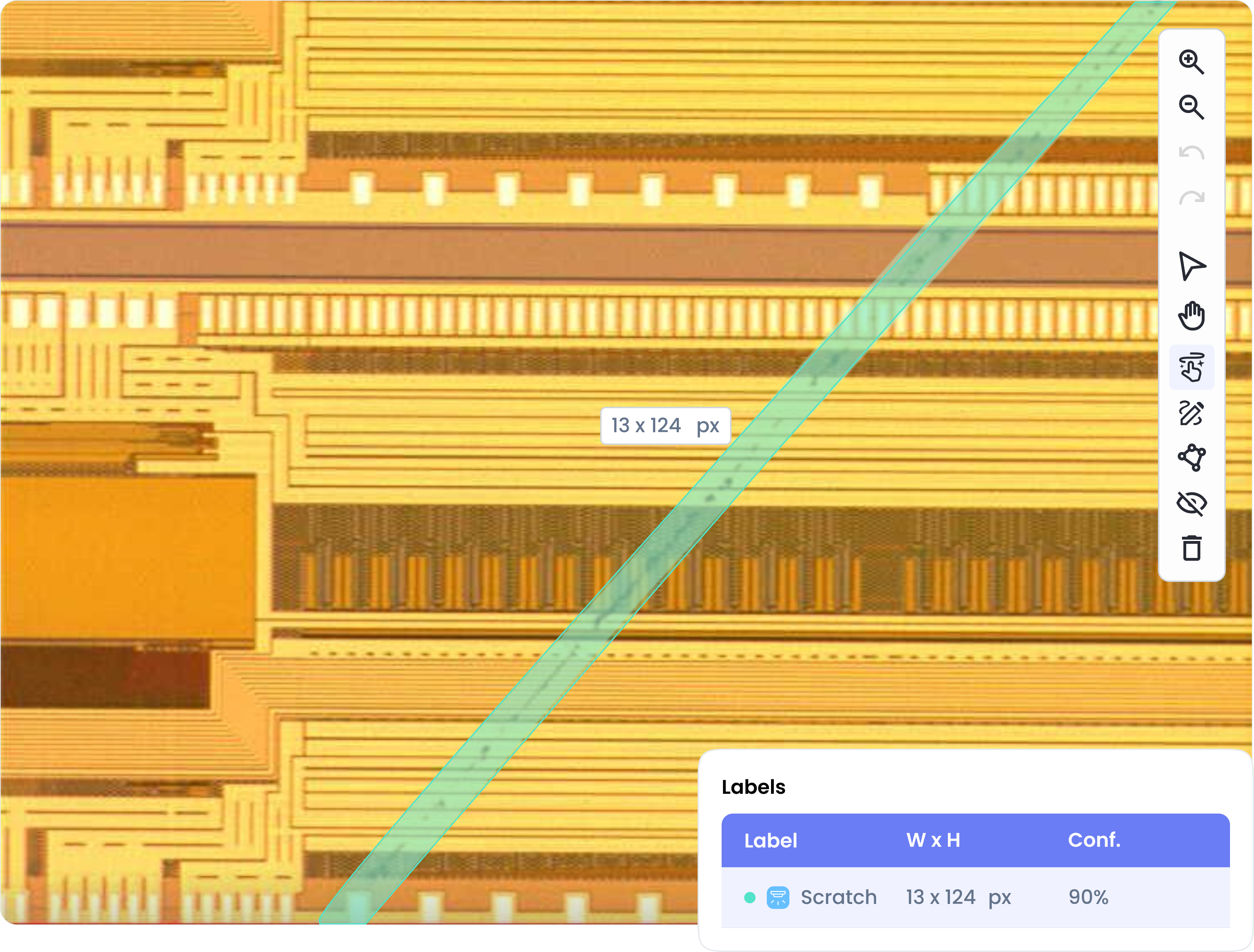

Pinpoint & Categorize Defects

AI Automated Defect Segmentation For Manufacturing

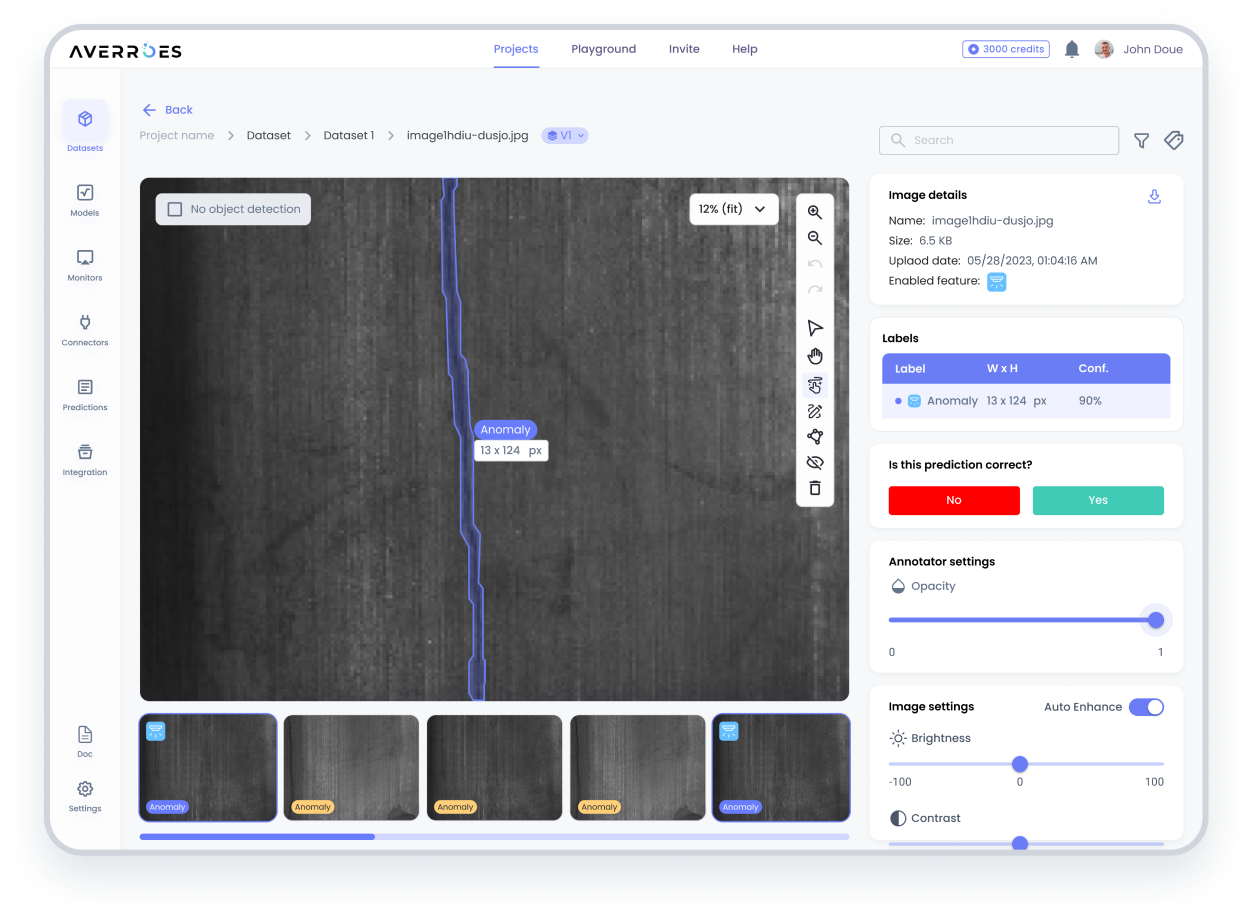

Defect Detection, Perfected. Pinpoint flaws with certainty. AI-driven inspection guarantees accurate detection, categorization , and classification using exact bounding boxes, regions, and classifications - minimizing downtime, maximizing quality.

Smarten Up Existing

Visual Inspection Equipment with AI

No new hardware or process changes required.

Accurate Defect Segmentation with Minimal Training Data

Train precise defect detection models with minimal data. Our AI adapts prior knowledge to new tasks, delivering fast, accurate results.

Easily train your models with just a few examples. Our Few-Shot Learning approach lets you adapt quickly to new defects, minimizing training time and maximizing efficiency.

Annotate images in a flash with our Labeling Tool. Simplify data preparation and empower your team to achieve high accuracy in defect classification without the hassle.

This powerhouse uses cutting-edge algorithms to identify and categorize defects accurately, ensuring near-zero false positives every time.

Easily integrate AI inspections into your workflows with minimal disruption, boosting productivity from day one. Choose from secure on-premise solutions for enhanced control or scalable cloud-based options for flexibility.

Keep improving with Feedback Learning. Our system learns from new data dynamically, enhancing accuracy and ensuring your inspections stay sharp against evolving challenges.

Precise Defect Boundaries

Achieve nanometer-level precision in defect detection without needing data science expertise. Our advanced segmentation models ensure your AI system is up and running within hours, requiring minimal data input for exceptional accuracy.

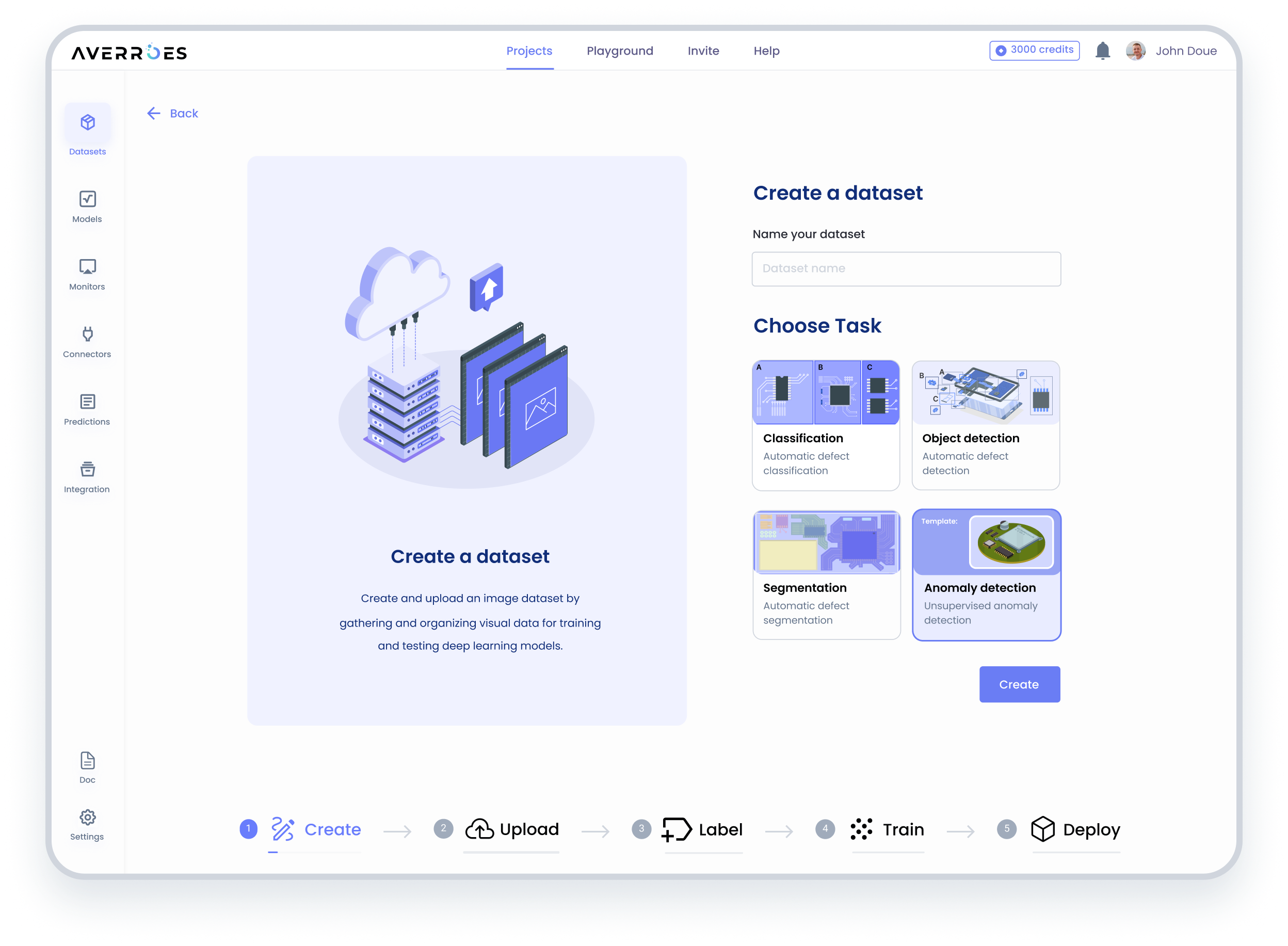

No-Code AI Platform

Easily build and deploy your own AI models with our No-Code AI Platform. Whether you're enhancing existing visual inspection equipment struggling with accuracy or creating a tailored AI defect classification model, achieving results is just a few simple steps away.

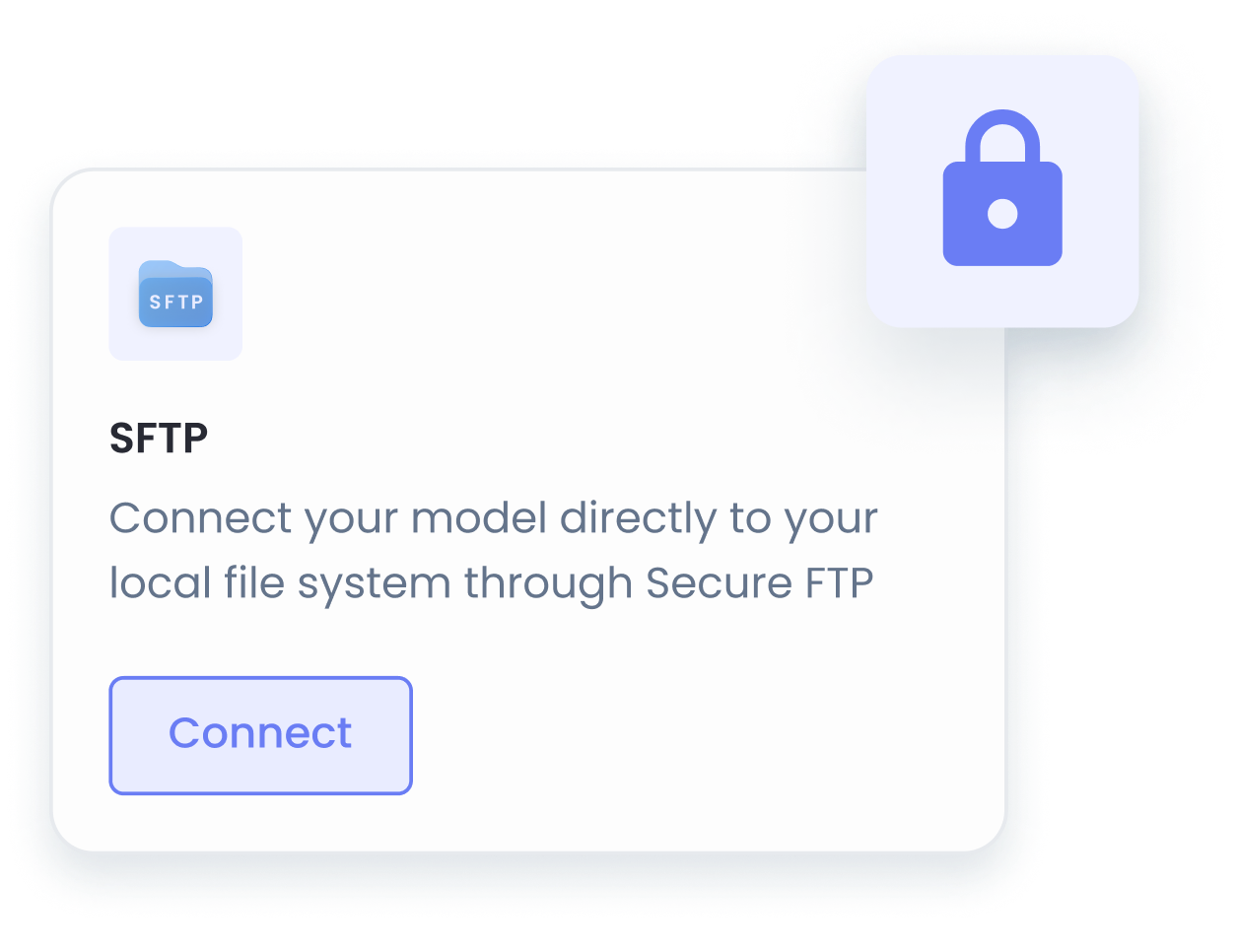

Privacy and Security

Choose On-Premise solutions for enhanced privacy, speed, and security, or opt for Cloud solutions for scalability and performance. Our cloud-agnostic architecture guarantees seamless integration, offering the flexibility you need to adapt to your unique operational requirements.

Continuously Learns from Data

Our Automated Defect Segmentation model outperforms traditional software by leveraging Active Learning to continuously learn from data. This enhances accuracy over time, ensuring your defect detection process remains adaptive and precise.

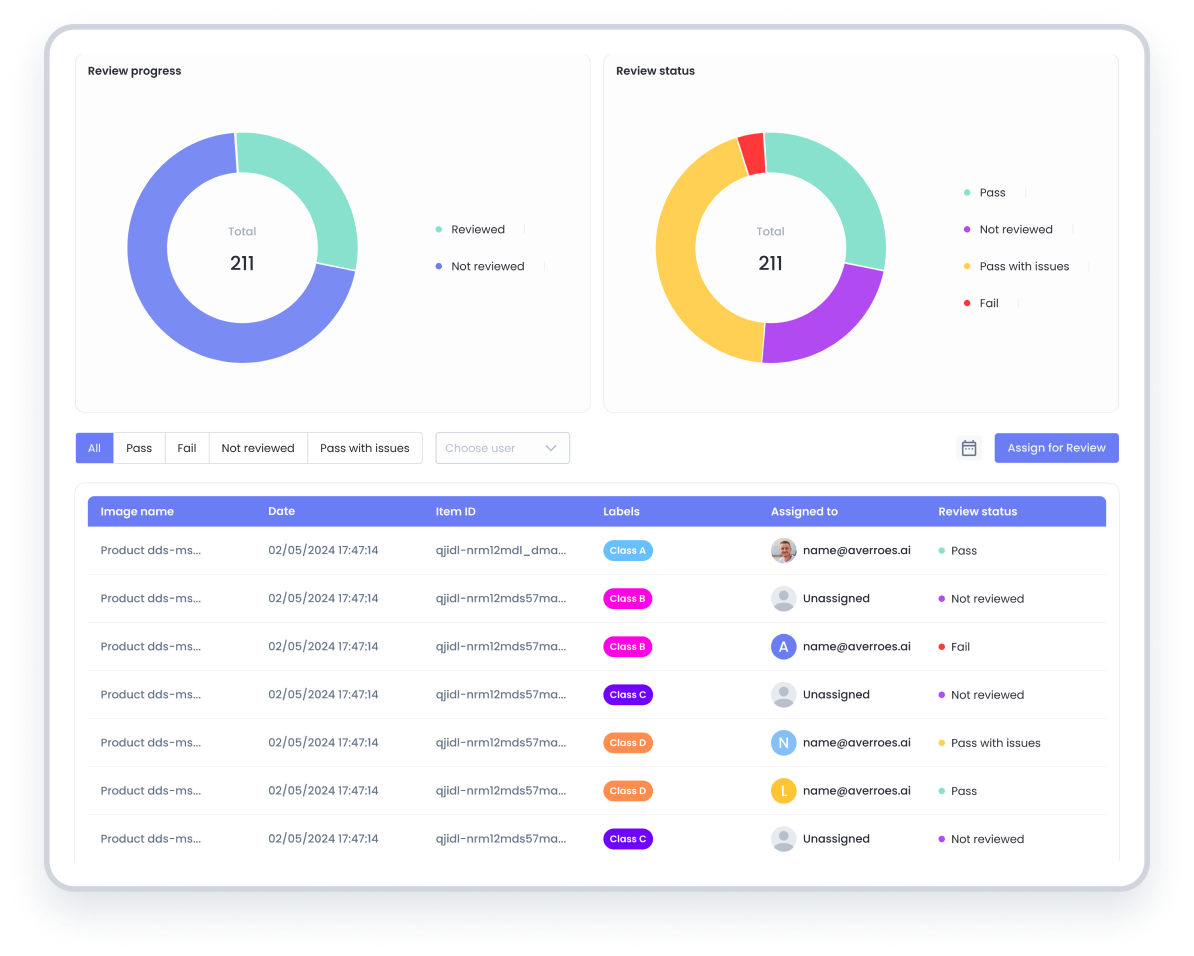

Automate Defect Judgment Process

Establish precise thresholds to identify only the defects that matter most. Our system empowers your judgment team to concentrate on throughput and yield improvement while we manage defect assessment—ensuring objectivity and eliminating subjectivity from your inspection process.

Capture Unknown Defects

The Averroes WatchDog feature guarantees that no defect goes unnoticed. Our advanced detection system captures every anomaly—both expected and unexpected. Unlike traditional equipment that only identifies pre-configured defects, our AI technology effectively detects all potential quality issues.

_pixian_ai 1.png)

Complete Storytelling

Analyze defects, wafers, and masks comprehensively—from A to Z. Our solution leverages historical data to provide deep insights, helping you understand the full context behind each defect.

We've experienced a remarkable 40-60% increase in submicron defect detection. Averroes has saved us over 300 hours/month/app of labor and increased our productivity by more than 30% .

Automation Manager @ Semiconductor OEM

Frequently asked questions

Averroes AI leverages advanced machine learning algorithms and active learning techniques to continuously adapt and enhance defect detection, ensuring high precision and minimal false positives.

Experience the Averroes AI Advantage

Elevate Your Visual Inspection Capabilities

Request a Demo Now